Wear Resistant Systems for Wood Processing

Maintain plant efficiency and integrity with Kingfisher Industrial

Plant degradation – we understand the pain

Kingfisher’s activities within the wood processing industry seemingly increase year on year. With the current trend towards the use of biomass as a substitute for fossil fuels within the power generation sector, then the wood industry has come under extensive pressure to use a greater percentage of recycled product. Blending this material with traditional lumber now accounts for the vast majority of finished goods produced. Despite the industry suffering from an amount of plant degradation due to contamination of lumber whilst being felled and handled, the problem of wear protection has become a major issue of late due to the influx of recycled product introduced into the process.

Extend plant and equipment service life

Kingfisher have been pioneering the use of wear resistant lining systems within the industry for many years. Having had substantial success throughout all areas of the plant, we feel confident of offering a system that will considerably extend the service life of process plant and equipment. Success can only be achieved by having a thorough understanding of the process in order to offer the solution to the problem, and through our activities whilst working with both the end user and OEM’s, we believe our interaction has saved the industry thousands if not millions of pounds worth of expenditure associated with replacement equipment.

The Solution Providers

From the planning phase of new plants to the modification of existing processing equipment, we can add significant value by advising on design criteria, manufacturing methods and most importantly protection, leading to increased plant availability and a greater return on investment with the knowledge that the asset value isn’t wearing away as fast as it used to.

Protection over replacement

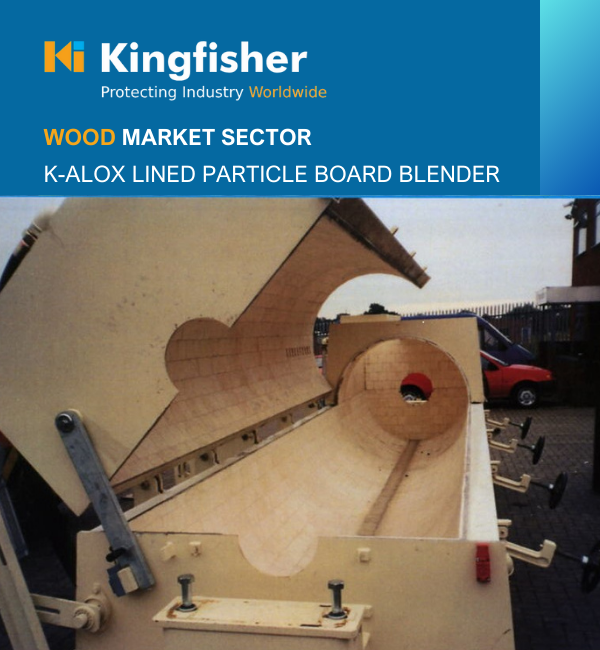

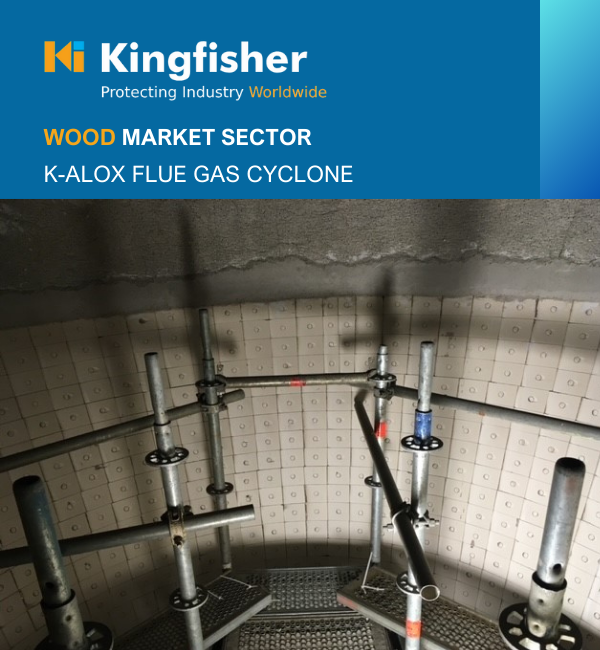

See below an example how Kingfisher Industrial can help with Wear Protection within the wood processing sector

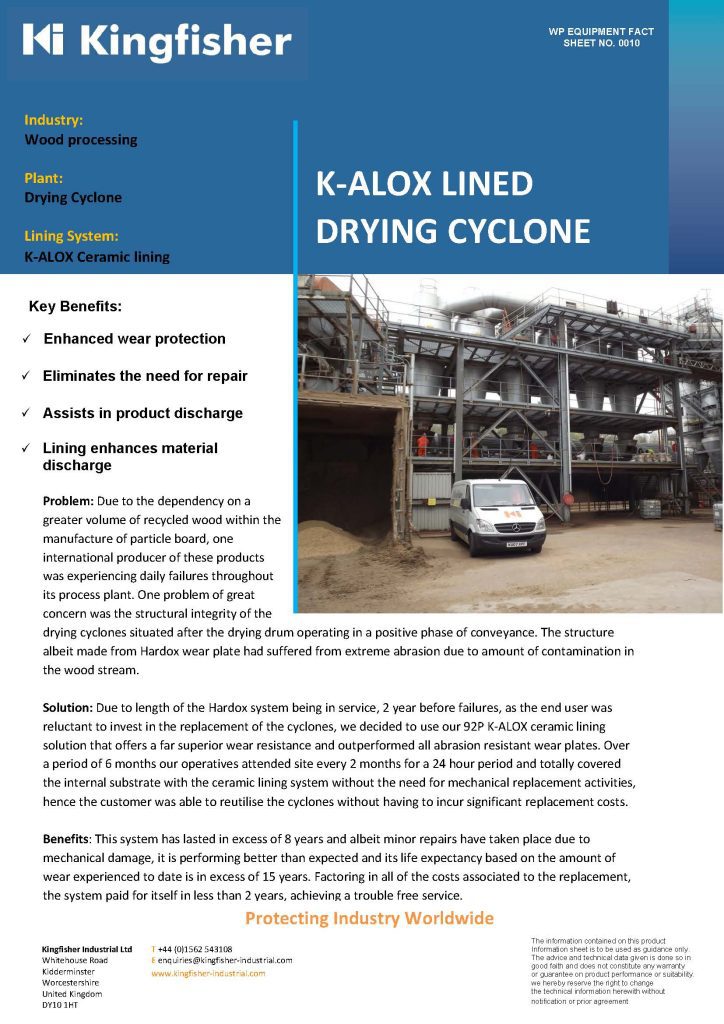

Problem

Due to the dependency on a greater volume of recycled wood within the manufacture of particle board, one international producer of these products was experiencing daily failures throughout its process plant. One problem of great concern was the structural integrity of the drying cyclones situated after the drying drum operating in a positive phase of conveyance. The structure albeit made from Hardox wear plate had suffered from extreme abrasion due to amount of contamination in

the wood stream.

Solution

Due to length of the Hardox system being in service, 2 year before failures, as the end user was reluctant to invest in the replacement of the cyclones, we decided to use our 92P K-ALOX ceramic lining solution that offers a far superior wear resistance and outperformed all abrasion resistant wear plates. Over a period of 6 months our operatives attended site every 2 months for a 24 hour period and totally covered the internal substrate with the ceramic lining system without the need for mechanical replacement activities, hence the customer was able to reutilise the cyclones without having to incur significant replacement costs.

Benefit

This system has lasted in excess of 8 years and albeit minor repairs have taken place due to mechanical damage, it is performing better than expected and its life expectancy based on the amount of wear experienced to date is in excess of 15 years. Factoring in all of the costs associated to the replacement, the system paid for itself in less than 2 years, achieving a trouble free service.

Key Benefits

Enhanced Wear Resistance

Eliminates the need for repair

Assists in product discharge

Lining enhances material discharge

more examples

View more case studies

If you’d like to see more case studies showing how we Kingfisher help solve problems and find solutions within the Wood Processing industry, please register your interest and we will get in touch.

Asset integrity experts

In identifying all relevant wear criteria and referencing a huge portfolio of wear protection materials and techniques, Kingfisher is able to make sound recommendations supported by firm performance guarantees. This option reduces the inherent risk of uneconomic investment as the costs of replacement can sometimes outweigh the initial CAPEX cost.

For more information about how Kingfisher Industrial assists the global Wood Processing industry, have a read through our industry specific brochure and get in touch.

Wear Protection

Kingfisher offer a full range of ceramic, metallic and polymer lining systems. With our experience protecting process plant and equipment in many industrial applications and the performance knowledge of the materials we provide we offer a totally unbiased solution for each individual application.

Ceramic

Metallic

Polymer