Wear protection – Polymers

Combat the problems of handling abrasive materials

Polymer Wear Resistant Solutions

With polymers such as rubber having the ability to absorb the shock of impact and repel the subsequent force, the detrimental effect of compression does not take place. With other polymer types such as polyethylene with its very low coefficient of friction that encourages the material to glide over it as opposed to scouring the surface, the effects of friction or sliding induced abrasion are reduced.

Polyurethanes in sheet form, cast components or spray applications have similar characteristics to rubber and polyethylene, offer wear-resistant performance based on an ability to counter the effects of impact and sliding induced abrasion in both mechanical and hydraulic states of conveyance.

The right solution?

Our range of Polymer materials include Expoxy Resin, UHMWPE Lining, Rubber Lining, Polyurethane Lining and High Density Polyethylene (PE-HD)

product details

K-KOTE

K-PLAS

K-TEX

K-THANE

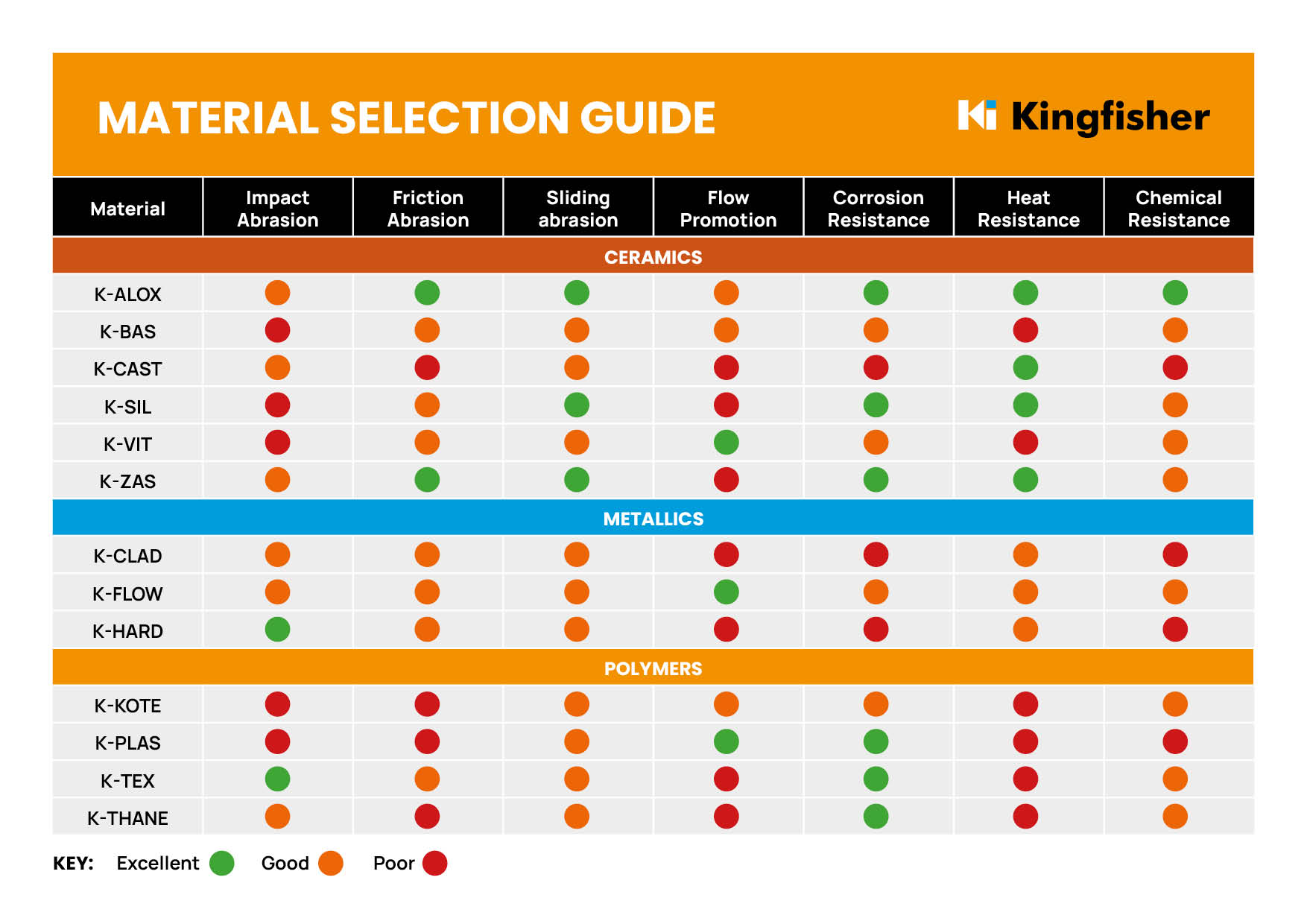

Material Group Resistance Guide

In support of industry needs, our service offering consists of a package of design, manufacture, protection and site installation of process plant equipment undertaking all activities in house utilising our fully trained and qualified personnel and resource facilities which reduces the risk of a breakdown in the supply chain. Performing to international standards of best practice with regard to quality control, environmental and health & safety, we align ourselves to the expectations of our valued customer base of internationally recognised OEMs, EPC contractors and end users many of whom are PLC’s operating on a global basis.

Talk to us

Speak to Kingfisher today to discuss the best wear protection solution for your business and how we can better protect your plant and operations to keep you running efficiently.

Design

Manufacture

Install