Wear protection – Ceramics

Combat the problems of handling abrasive materials

Ceramic Wear Resistant Solutions

Using ceramic technology to combat the problems of handling abrasive materials has served industry very well for many years and continues to evolve to this day. From simple cast products introduced in the early 20th century to state-of-the-art sintered components used in today’s innovative mechanical sector, the percentage of market share that ceramic now enjoys, continues to grow year on year.

Despite this proven success, there is still doubt in some instances whether ceramic can outperform steel by a significant factor with regard to wear life expectancy. Many industries that once had this perspective are now benefiting from investment in technology that previously would never have been considered.

Our Ceramic Range

Like all materials, ceramic can have a positive and a negative impact, and correctly identifying all operating criteria before it use is vital to ensure a return on investment.

Our Ceramic range of materials include High Alumina, Fused Cast Basalt, Monolithic Ceramic, Silicone Carbide, Fully Vitrified and Fused Corundrum.

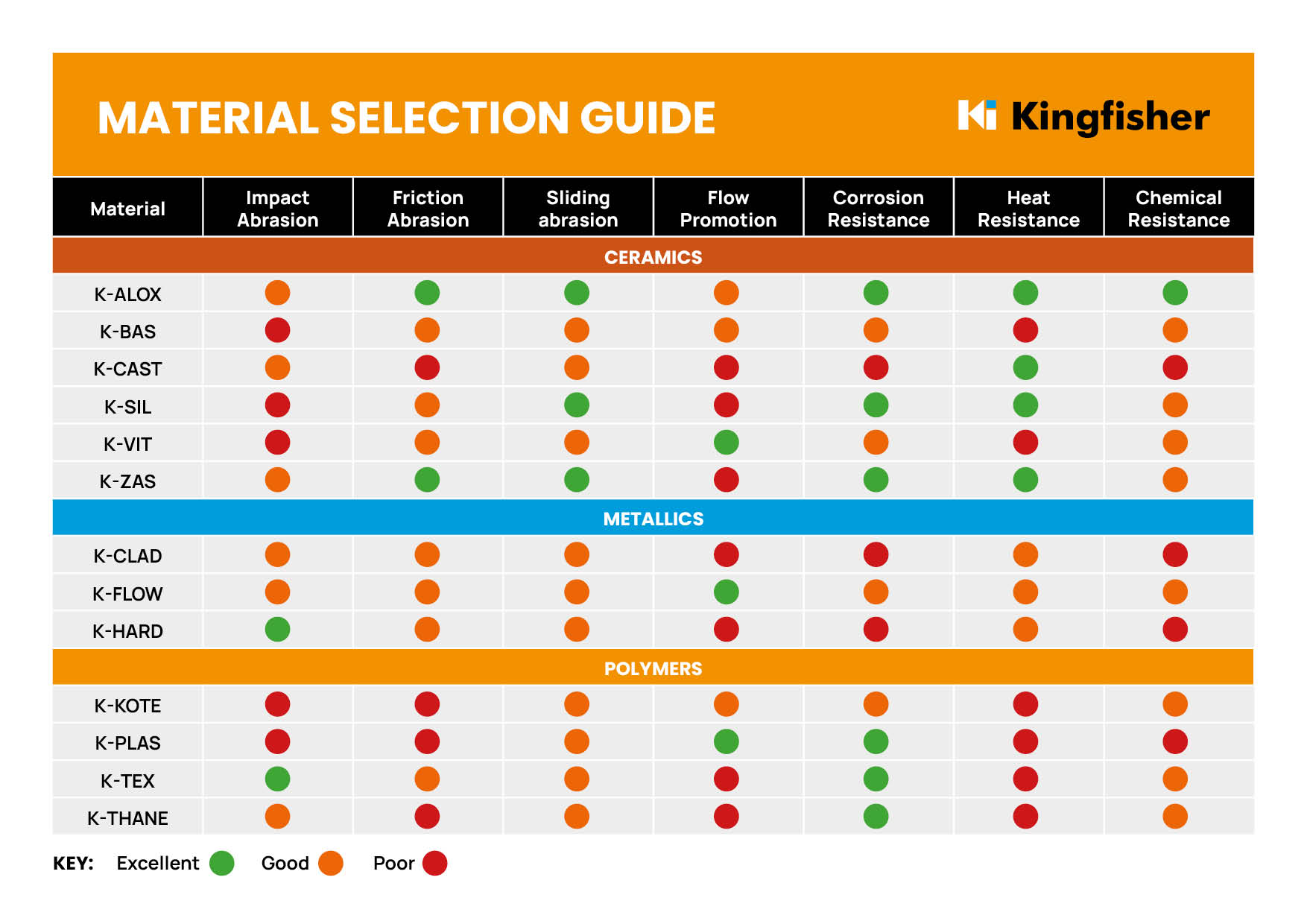

Material Group Resistance Guide

In support of industry needs, our service offering consists of a package of design, manufacture, protection and site installation of process plant equipment undertaking all activities in house utilising our fully trained and qualified personnel and resource facilities which reduces the risk of a breakdown in the supply chain. Performing to international standards of best practice with regard to quality control, environmental and health & safety, we align ourselves to the expectations of our valued customer base of internationally recognised OEMs, EPC contractors and end users many of whom are PLC’s operating on a global basis.

Talk to us

Speak to Kingfisher today to discuss the best wear protection solution for your business and how we can better protect your plant and operations to keep you running efficiently.

Design

Manufacture

Install