Wear Resistant Systems for Mining

Maintain plant efficiency and integrity with Kingfisher Industrial

Plant erosion – we understand the pain

Albeit unfashionable, coal is one resource the world cannot do without and, despite increasing legislation in its use, its benefits to industry and society ensure that it will be around for many years to come. Continual research into the reduction of coal combustion effects improve year on year and will inevitably reach a stage where the markets consider the benefits of this plentiful and accessible resource a viable option to the world’s energy needs once again.

Protect equipment to increase efficiency and ensure longevity

As soon as coal is mined, the challenge of handling the various sizes, types and blends begins. From the face of deep or open cast mines, the effects of coal’s high silica content starts to erode both the plant and equipment used to process it together with the producer’s profits. Regardless of this, the industry has continually invested in machinery to maximise its opportunities and developed more efficient equipment to handle and process an annually increasing tonnage.

Protect equipment to increase efficiency and ensure longevity

As soon as coal is mined, the challenge of handling the various sizes, types and blends begins. From the face of deep or open cast mines, the effects of coal’s high silica content starts to erode both the plant and equipment used to process it together with the producer’s profits. Regardless of this, the industry has continually invested in machinery to maximise its opportunities and developed more efficient equipment to handle and process an annually increasing tonnage.

The Solution Providers

In such a well-established industry, there are many proven equipment protection techniques which have been successfully employed to enhance the efficiency of modern production methods. These ceramic, metallic or polymer lining systems can be designed into the fabric of new equipment or retrofitted to existing plant by redesigning the structure or installing a lining directly into the existing fabrication.

Protection over replacement

See below an example how Kingfisher Industrial can help with Wear Protection within the Mining industry

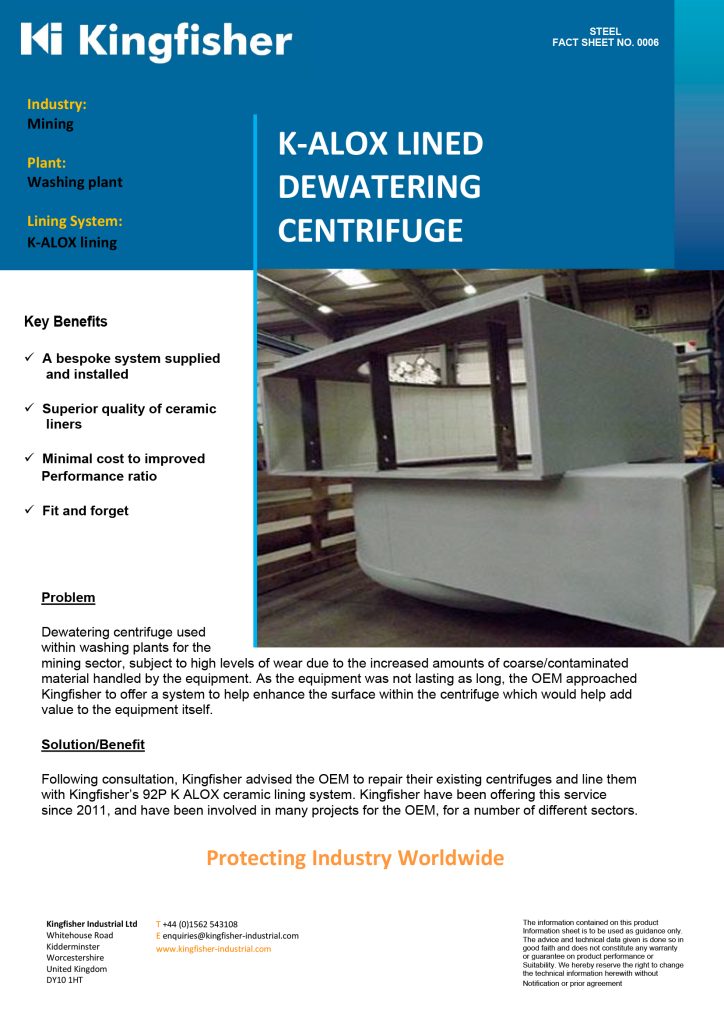

Problem

Dewatering centrifuge used within washing plants for the mining sector, subject to high levels of wear due to the increased amounts of coarse/contaminated material handled by the equipment. As the equipment was not lasting as long, the OEM approached

Kingfisher to offer a system to help enhance the surface within the centrifuge which would help add value to the equipment itself.

Solution & Benefit

Following consultation, Kingfisher advised the OEM to repair their existing centrifuges and line them with Kingfisher’s 92P K ALOX ceramic lining system. Kingfisher have been offering this service since 2011, and have been involved in many projects for the OEM, for a number of different sectors.

Key Benefits

A bespoke system supplied & installed

Superior quality of ceramic liners

Minimal cost to improved performance ratio

Fit and forget

more examples

View more case studies

If you’d like to see more case studies showing how we Kingfisher help solve problems and find solutions within the mining industry, please register your interest and we will get in touch.

Asset integrity experts

In identifying all relevant wear criteria and referencing a huge portfolio of wear protection materials and techniques, Kingfisher is able to make sound recommendations supported by firm performance guarantees. This option reduces the inherent risk of uneconomic investment as the costs of replacement can sometimes outweigh the initial CAPEX cost.

For more information about how Kingfisher Industrial assists the global Mining industry, have a read through our industry specific brochure and get in touch.

Wear Protection

Kingfisher offer a full range of ceramic, metallic and polymer lining systems. With our experience protecting process plant and equipment in many industrial applications and the performance knowledge of the materials we provide we offer a totally unbiased solution for each individual application.

Ceramic

Metallic

Polymer