Wear Resistant Systems for Metals

Maintain plant efficiency and integrity with Kingfisher Industrial

Reducing omissions – we understand the pain

Having to comply with constant regulatory initiatives make the task of producing both metals and profit a difficult balance regardless of the economic backdrop. This challenge will not cease as the need for ever reducing omissions levels will drive the industry, and only by compliance will operations continue to trade. In meeting these challenges the industry depends on its supplier base to support it by introducing new technology and continue improving best practice in order to ensure that the process is as efficient as possible.

Improve your process and efficiency

Complimenting technological improvements, plant engineers and managers alike have significant responsibility in the maintenance and continual investment in the plant and without their input the operation will be short lived.

Working alongside plant engineers, Kingfisher continually look to improve its level of service offered to the industry. In reviewing the current operational process and by understanding what improvements have been made and the reasons why, we believe that by identifying what causes the problem, we can offer the solution. With a vast experience in a host of industrial sectors, very rarely do we encounter a unique problem. Having that understanding and being able to reference the proposed solution to a previously undertaken successful application gives all parties concerned the confidence to invest.

The Solution Providers

From receipt of minerals at the reception head, via ship or train, we follow the product through the process in either a raw, semi of finished state through to the handling and treatment of by-products and the cleaning operations associated with omissions. Our ability to be able to relate with the engineers is second to none and by offering a package of design, manufacture, protection and installation, maintains total control through the use of own resources ensuring service, quality and value for money.

Protection over replacement

See below an example how Kingfisher Industrial can help with Wear Protection within the Metals industry

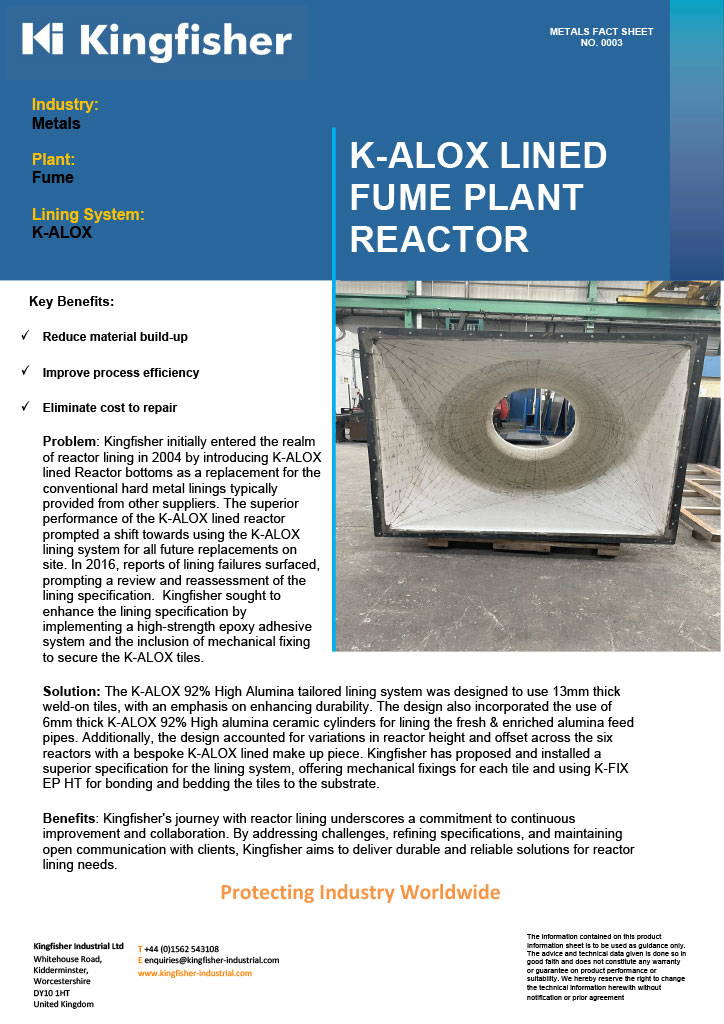

Problem

Reports of lining failures surfaced, prompting a review and reassessment of the lining specification. Kingfisher sought to enhance the lining specification by implementing a high-strength epoxy adhesive system and the inclusion of mechanical fixing to secure the K-ALOX tiles.

Solution

The K-ALOX 92% High Alumina tailored lining system was designed to use 13mm thick weld-on tiles, with an emphasis on enhancing durability. The design also incorporated the use of 6mm thick K-ALOX 92% High alumina ceramic cylinders for lining the fresh & enriched alumina feed pipes. Additionally, the design accounted for variations in reactor height and offset across the six reactors with a bespoke K-ALOX lined make up piece.

Benefit

Kingfisher’s journey with reactor lining underscores a commitment to continuous improvement and collaboration. By addressing challenges, refining specifications, and maintaining open communication with clients, Kingfisher aims to deliver durable and reliable solutions for reactor lining needs.

Key Benefits

Reduce material build-up

Eliminate cost to repair

Improve process efficiency

more examples

View more case studies

If you’d like to see more case studies showing how we Kingfisher help solve problems and find solutions within the Metals industry, please register your interest and we will get in touch.

Asset integrity experts

In identifying all relevant wear criteria and referencing a huge portfolio of wear protection materials and techniques, Kingfisher is able to make sound recommendations supported by firm performance guarantees. This option reduces the inherent risk of uneconomic investment as the costs of replacement can sometimes outweigh the initial CAPEX cost.

For more information about how Kingfisher Industrial assists the global metal industry, have a read through our industry specific brochure and get in touch.

Wear Protection

Kingfisher offer a full range of ceramic, metallic and polymer lining systems. With our experience protecting process plant and equipment in many industrial applications and the performance knowledge of the materials we provide we offer a totally unbiased solution for each individual application.

Ceramic

Metallic

Polymer